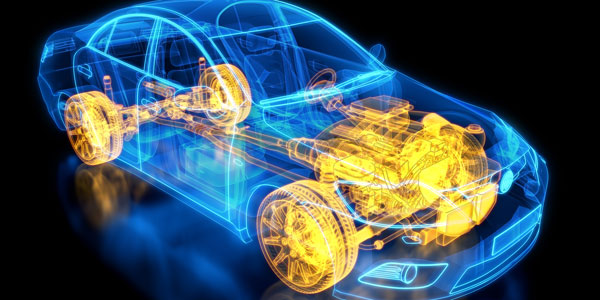

We offer comprehensive and in depth test services. In today’s automotive and transportation industries, technologies play a very important role in order to specify masked and unknown problems by series of in-depth tests which were not available before. New vehicle applications and platforms consisting of different conditions require very sophisticated testing labs and benches for every detail especially for the powertrain and transmission complexed components. Our access to very complicated, most advanced and versatile test platforms ensures complete reliable test results.

TRANSMISSION TESTING AND VALIDATION

We have in depth transmission tests on test benches which can create almost 90% of the environmental situations. More than 30 parameters are checked and analyzed for maximum performance output. In addition rolling tests are also available if needed.

ELECTRONIC SYSTEM AND COMPONENTS TEST AND VALIDATION

We do electronic system development and checking and testing for our projects or those which are in the test phase in our testing facilities. A very important part of any project development which plays a major key in final performance. Analysis of data, fault finding and problem solving on data which acquired from CAN, LIN, FLEX-RAY or MOST is one of the major steps in this segment.

POWERTRAIN TESTING AND VALIDATION

We also perform sophisticated engine and powertrain tests on test benches. Up to 35 parameters will be tested to identify the performance or even weaknesses of engines.