Functionality

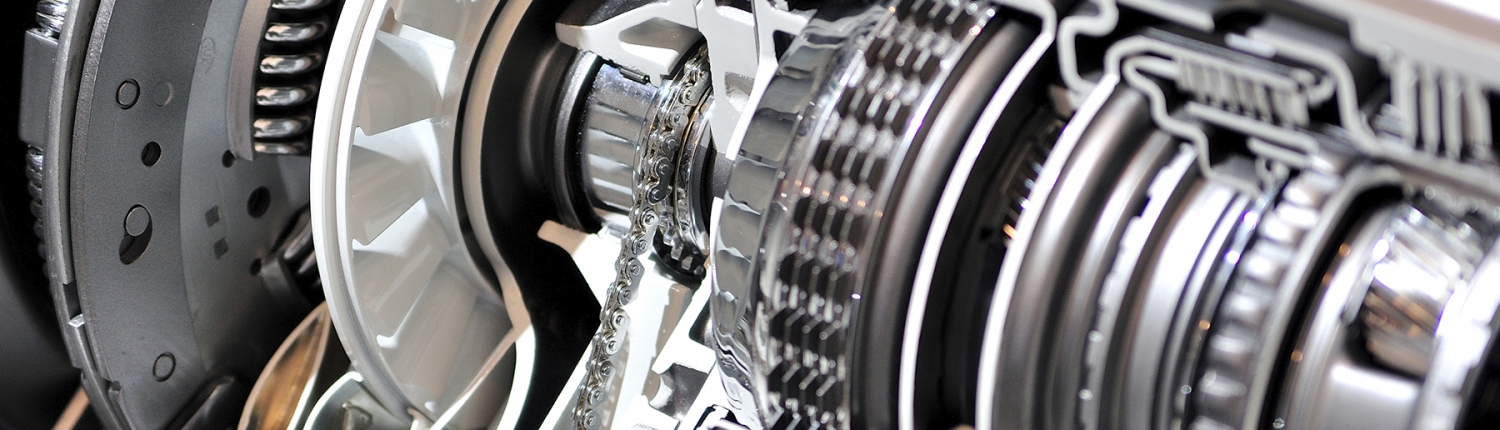

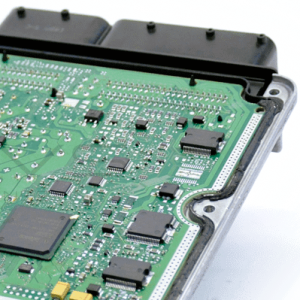

There are many functions that a customer wants from the transmission system especially from automatic one. Apart from smooth shifting and perfect ratios which are also available in a manual gearbox, a well programed transmission behavior like a pro driver is expected from one. That’s the job we do. Functions will be packed into the TCU as a must, which work alongside with engine management system to bring perfect functionality with reliability and economy for every driver.

Fuel and Emission control

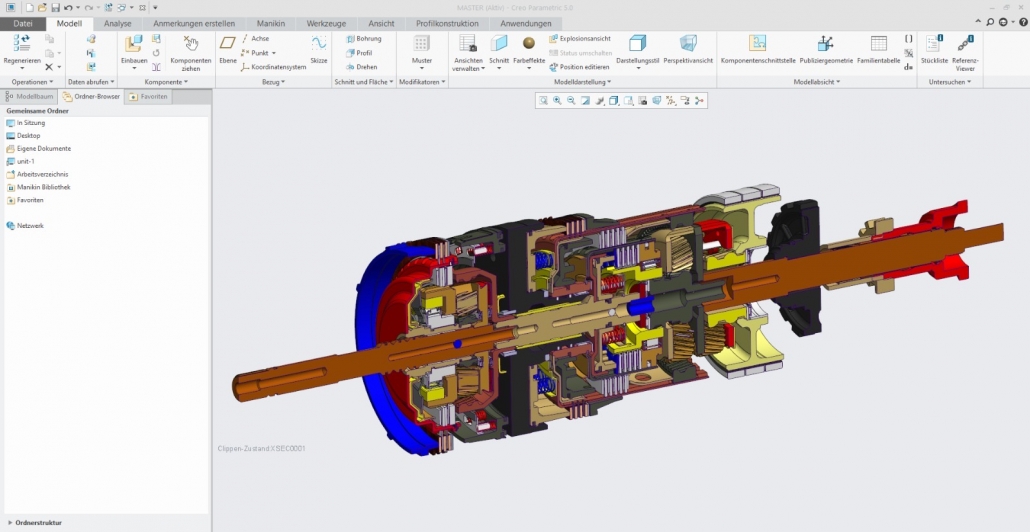

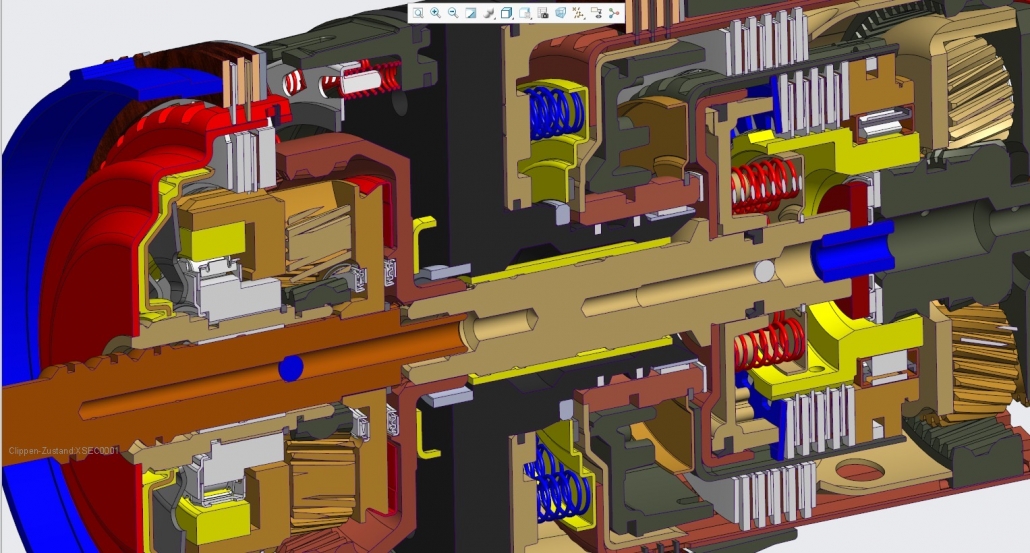

When we design an automatic transmission, we always look forward to reduce two things, fuel consumption and thus emissions. But on the other hand performance should not be sacrificed by economy. This is the magic of Burg Germany engineering facilities. We always tune up the optimum with maximum.

Cost effective production

Designed for production. From concept to SOP. It all starts from the beginning. Vehicle development for todays production facilities rely on engineered production performance. That is what we put into each of every development project we aim for mass production. In another words, cost effective production engineering systems guarantees less resources for maximum production.